- Home

- About Us

- R&D and Innovation

- Business Portfolio

- After-sale Service

-

Investor Relations

Investor Relations

-

Join Us

Join Us

- Contact Us

Business Portfolio

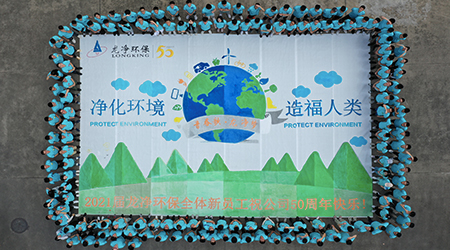

Air Pollution Control